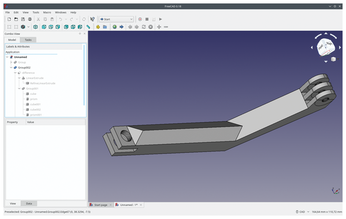

Technical 3D design using FreeCAD

Tutorials – FreeCAD

Designing simple shapes in OpenSCAD is easy, but if you want to print complex machines with multiple interlocking pieces, you need to bring out the big guns. That's where FreeCAD comes in handy.

In the last two issues [1, 2], I discussed designing 3D objects using scripts in OpenSCAD [3]. That was easy and fun, as well as an effective way of creating simple objects. But as soon as the number of faces and moving parts starts to grow, the lines of code multiply exponentially making your OpenSCAD designs unwieldy and difficult to troubleshoot.

Fortunately, FreeCAD [4] is a full-featured graphical software application that takes over from OpenSCAD for more complex printing. You can even import your OpenSCAD designs into FreeCAD (Figure 1)!

[...]

Buy this article as PDF

(incl. VAT)

Buy Linux Magazine

Subscribe to our Linux Newsletters

Find Linux and Open Source Jobs

Subscribe to our ADMIN Newsletters

Support Our Work

Linux Magazine content is made possible with support from readers like you. Please consider contributing when you’ve found an article to be beneficial.

News

-

Linux Foundation Reports that Open Source Delivers Better ROI

In a report that may surprise no one in the Linux community, the Linux Foundation found that businesses are finding a 5X return on investment with open source software.

-

Keep Android Open

Google has announced that, soon, anyone looking to develop Android apps will have to first register centrally with Google.

-

Kernel 7.0 Now in Testing

Linus Torvalds has announced the first Release Candidate (RC) for the 7.x kernel is available for those who want to test it.

-

Introducing matrixOS, an Immutable Gentoo-Based Linux Distro

It was only a matter of time before a developer decided one of the most challenging Linux distributions needed to be immutable.

-

Chaos Comes to KDE in KaOS

KaOS devs are making a major change to the distribution, and it all comes down to one system.

-

New Linux Botnet Discovered

The SSHStalker botnet uses IRC C2 to control systems via legacy Linux kernel exploits.

-

The Next Linux Kernel Turns 7.0

Linus Torvalds has announced that after Linux kernel 6.19, we'll finally reach the 7.0 iteration stage.

-

Linux From Scratch Drops SysVinit Support

LFS will no longer support SysVinit.

-

LibreOffice 26.2 Now Available

With new features, improvements, and bug fixes, LibreOffice 26.2 delivers a modern, polished office suite without compromise.

-

Linux Kernel Project Releases Project Continuity Document

What happens to Linux when there's no Linus? It's a question many of us have asked over the years, and it seems it's also on the minds of the Linux kernel project.